We developed EBS for the operation in electric or hybrid vehicles on one axle. A vehicle specific wiring harness can be purchased (vehicle specific definition is needed).

The EBS is specifically adapted for motorsport use. Individual car parameters like e.g. brake pads friction can be calibrated with software free of charge. Please contact your Bosch Motorsport dealer for further information.

- Downloads

- Features

- Technical Specifications

- Communication

- Installation Notes

- Ordering Information

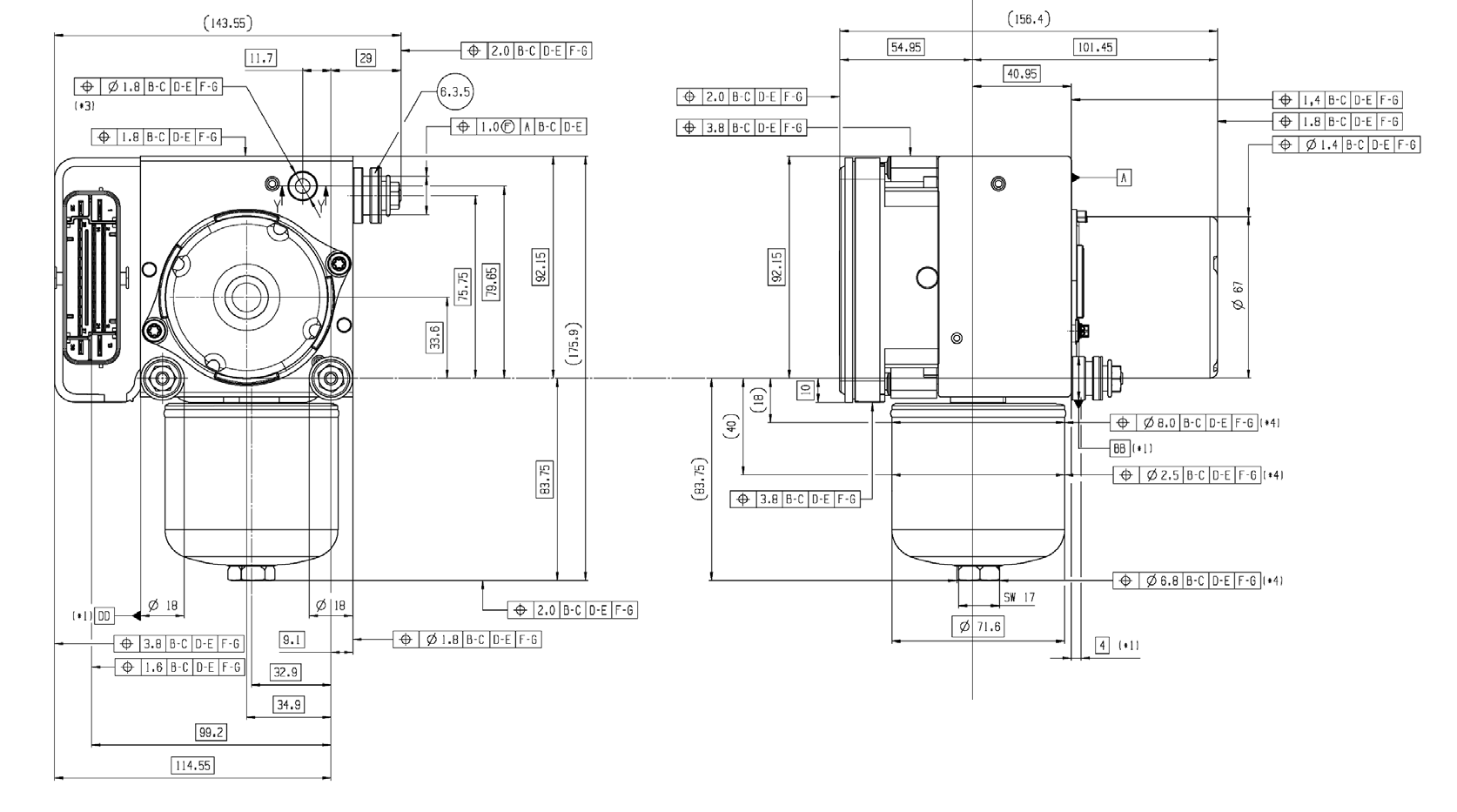

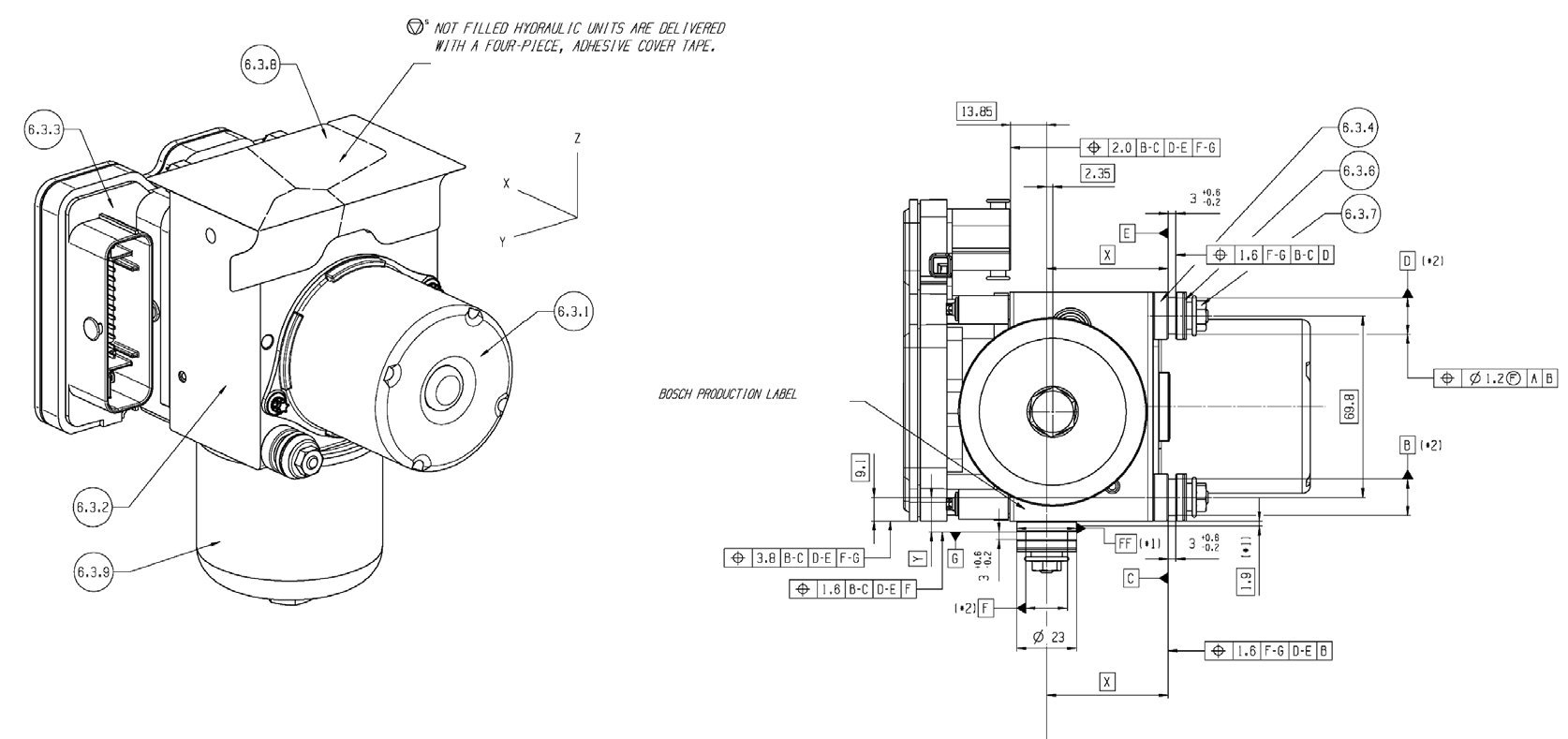

- Dimensions

- Legal Restrictions

Downloads

Features

- Suitable for one axle use

Technical Specifications

Mechanical Data

Hydraulic unit | |

|---|---|

Serial housing, dust- and damp-proof | |

Vibration damped circuit board | |

38 pin connector | |

6 hydraulic valves for inlet/outlet | |

1 separation backup valve | |

1 electric pump motor | |

1 hydraulic accumulator | 160 bar/90 cm3 |

Standard fittings | M12 x 1 |

Size | 176 x 144 x 157 mm |

Operating temperature | -30 to 130°C |

Max. shock | 50 g less than 6 ms |

Max. working pressure | 130 bar; max. recommended locking pressure 120 bar |

Max. pressure gradient | up to 2,000 bar/s |

Pressure Medium

DOT 4 brake fluid |

DOT 5.1 brake fluid |

Electrical Data

Supply voltage | 10 to 16 V |

Max. peak voltage | 35 V for 200 ms |

Max. peak at start | <165 A |

Current consumption Pump | <40 A |

Current consumption Relay | <16.5 A |

Power consumption Electronics | <1.5 A |

Inputs

1 x PWM Target (Pressure or Torque) |

1 x PWM input calliper pressure |

1 x CAN1; 500 k or 1 Mb selectable |

1 x CAN1 DC (Daisy Chain) |

EBS function switch 6 positions via CAN1 |

Outputs

EBS warning light (MIL) via CAN1 |

EBS diagnostic via CAN1 |

Required Additionals

Mounting Board for Hydraulic Unit |

|

Pressure Sensors Fluid PSS-260 | 2 required |

Com Interface MSA Box II | Required for communication and programming, not mandatory if available |

Spare Parts

Mounting Rubber Elements Kit | 5 sets (10 units Ø 18 mm; |

Component Weights

Hydraulic Unit | 3,630 g |

Mounting Board for Hydraulic Unit | 300 g |

2 Pressure Sensors Fluid PSS-260 | 40 g/each |

Vehicle specific wiring harness with motorsport connectors | Depends on version |

Pin Configuration

1 | UB_MR |

... |

|

13 | GND_MR |

14 | CAN1M |

15 | CAN1M-DC |

... |

|

25 | UB_VR |

26 | CAN1P |

27 | CAN1P-DC |

28 | WAU_IN |

... |

|

31 | PWM Gnd |

... |

|

33 | PWM 5 V |

... |

|

36 | P_Target_PWM |

37 | P Caliper PWM in |

38 | GND_ECU |

Communication

Installation Notes

Maintenance Interval (brake fluid change, bleeding): 220 h or a maximum of two years.

The load on the hydraulic unit in racing is much higher than in pure road operation, therefore we recommend a replacement of the unit after one year.

Ordering Information

Electronic Brake System EBS

Order number: F02U.V02.900-01

Com Interface MSA-Box II

Not mandatory if available

Order number: F02U.V00.327-03

Mounting Board for Hydraulic Unit

Order number: 0265.Y5H.505-01

Pressure Sensor Fluid PSS-260

Order number: 0261.545.040

Mounting Rubber Elements Kit

Spare Part

Order number: F02U.V03.318-01

Dimensions

Legal Restrictions

The sale of this product in Mexico is prohibited.

Due to embargo restrictions, sale of this product in Russia, Belarus, Iran, Syria, and North Korea is prohibited.