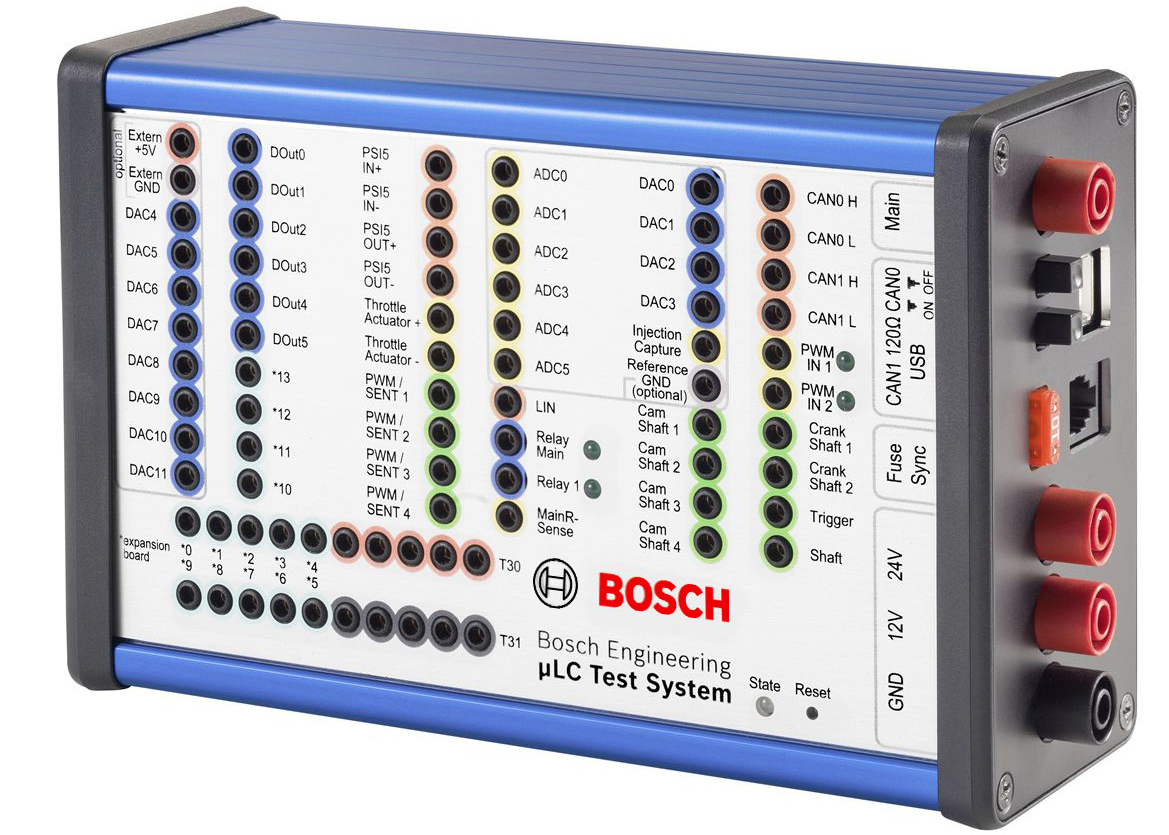

The new and modern hardware-in-the-loop test system µLC Test System is suitable for mobile application, measuring a compact 17 x 11 x 6 cm. Initial test setup typically takes under ten minutes, since the system allows for a simple test setup.

It is a compact open-loop test system for quality assurance of control unit development and combines the simulation of all typical automotive sensors and communication protocols in one unit. Its interface is user-friendly and enables an easy operation and evaluation.

The µLC Test System is especially used for automotive control units with typical interfaces for sensors and bus systems such as analog/digital inputs and outputs, PWM signals, SENT, CAN, LIN and speed sensors.

Downloads

Features

- User-friendly interface

- Functions can be extended with Expansion Boards

- Prepared for test automation

- Favorable test setup, consuming low space

- Simulation of typical automotive interfaces combined in one unit

Application

Engine Speed Simulation

- Up to 20,000 rpm

- Supported sensors: Hall, inductive, DG23i, TL4953

- Up to 2 crankshafts, up to 4 camshafts

- each is independently configurable

- auxiliary shaft

- -180 to 180° camshaft adjustment

- Oscilloscope trigger signal for easier monitoring

- Error simulation for engine position management EPM

Vehicle Busses

- 2 * CAN, up to 1 MBit/s,

switchable 120 Ohm CAN bus terminator - LIN Master/Slave

- SENT, full J2716 Jan. 2012 standard

4 Outputs, alternative to PWM output

Analog Interfaces

- 8 * 10 bit DAC 0 to 5 V, max. 5 mA

Internal or external supply - 4 * 12 bit DAC 0 to 5 V, max. 5 mA

- 6 * 12 bit ADC 0 to 40 V, GND reference

Digital Interfaces

- 6 * Digital Out, max. 200 mA in total

Output modes: Ground, 12 V, High impedance - 2 * Relays, max. 10 A, separate ECU power supply possible and incl. main relay sensing

- 2 * PWM input, 8 Hz to 20 kHz

- 4 * PWM output, max. 90 mA in total,

0.1 Hz to 20 kHz

Output voltages: 12 V, 5 V, GND - Complex PWM with sub signals, each separately adjustable in frequency, duty cycle and pulse count

Additional Features

- Throttle body simulation

- Cylinder pressure simulation

- Up to 8 cylinders with one device

- Expandable with multiple devices

- USB connection completely galvanic decoupled

- All in- and outputs short-circuit protected and ESD protected

- EMC tested

- Expansion boards for additional HW features

- Multi device support with sync option for engine speed signals

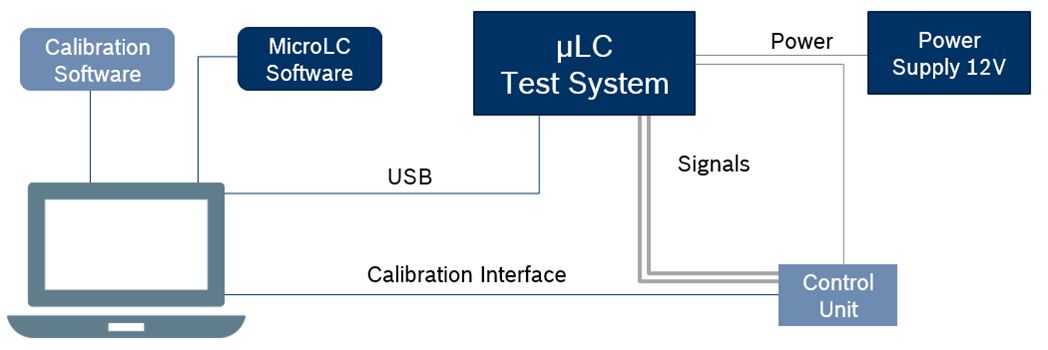

Test Setup

Note: Calculation intensive modules like cylinder pressure simulation can cause a limitation of e.g. the max. engine speed.

Technical Specifications

Operating voltage | 12 V DC |

Current consumption | typ. < 1 A |

ECU voltage | 12 V / 24 V DC |

ECU current | 10 A |

Permissible operation temperature | 0 to 40°C |

Housing material | Aluminum |

Dimensions | 175 x 107 x 61 mm |

Weight | 690 g |

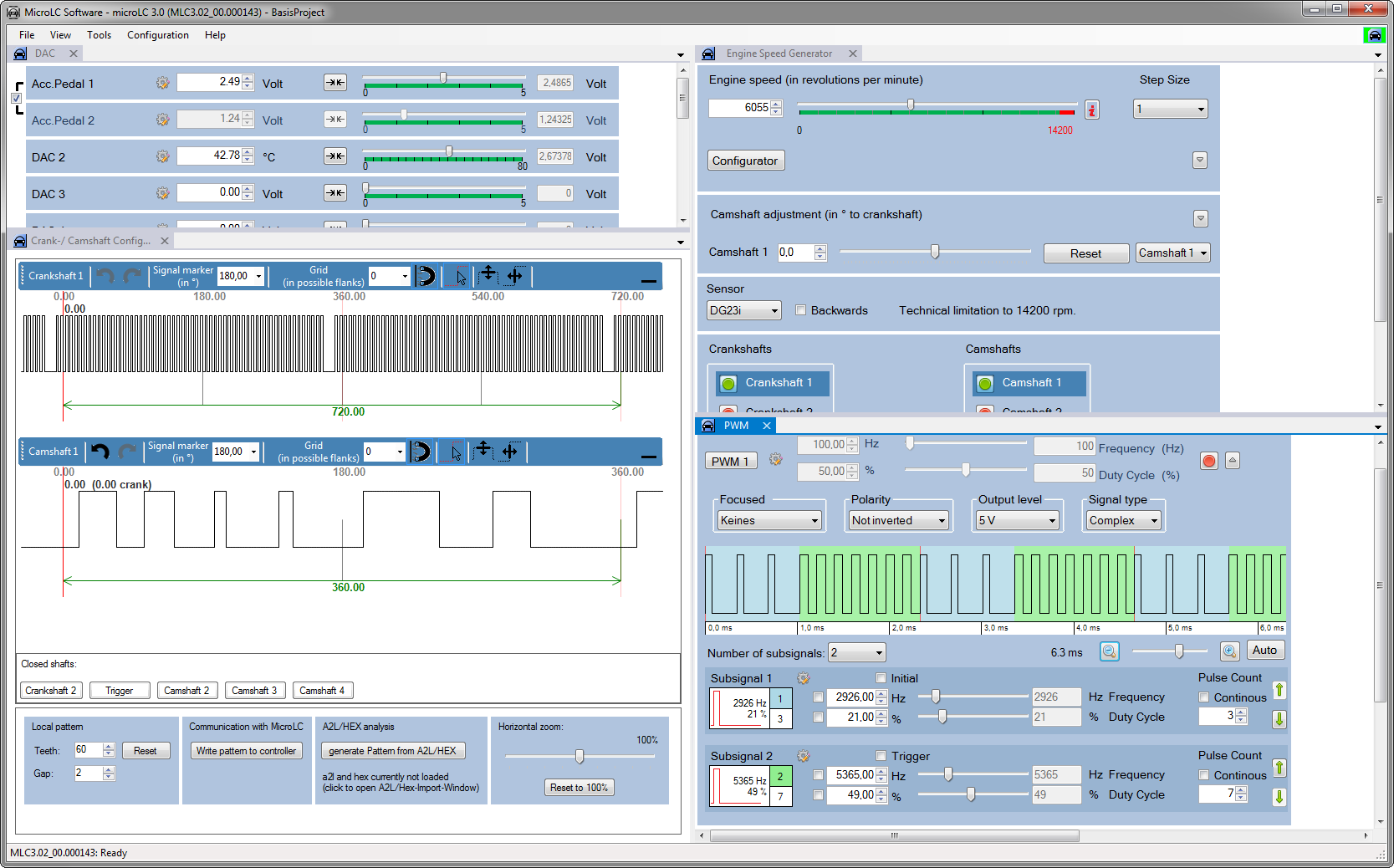

The screenshot shows the MicroLC Software with analog outputs, crank-/ camshaft, RPM and complex PWM.

Update and Support Subscription

- Free in the first year of use, chargeable from the second year

Ordering Information

µLC Test System

Order number: F02U.V02.303-02

Software Options

Update and Support Subscription

Order number: F02U.V02.838-01

Accessories

Expansion Board CAN-FD

Order number: F02U.V03.095-01

Expansion Board Current Loop Interface

Order number: F02U.V02.889-01

Expansion Board Digital Multichannel Pot.

Order number: F02U.V03.129-01

Expansion Board Digital Outputs

Order number: F02U.V02.904-01

Expansion Board FlexIO

Order number: F02U. V03.360-01

Legal Restrictions

The sale of this product in Mexico is prohibited.

Due to embargo restrictions, sale of this product in Russia, Belarus, Iran, Syria, and North Korea is prohibited.